It is generally not recommended to leave solder on the tip of a soldering iron, as this can cause various problems. Solder can solidify and form a crust on the tip of the iron, making it difficult to use and reducing its ability to transfer heat to the components being joined. In addition, leaving solder on the tip of the iron can increase the risk of accidents, such as burns or fires, and can damage the iron itself.

There are several reasons why leaving solder on the tip of a soldering iron is not recommended. First, solder can solidify and form a crust on the iron's tip, making it difficult to use. When the tip of the iron is covered in solidified solder, it can be difficult to apply heat to the joined components, and the solder may not flow properly. This can result in weak or unreliable joints and make soldering more difficult and time-consuming.

Second, leaving solder on the tip of the iron can reduce its ability to transfer heat to the components being joined. The tip of a soldering iron is designed to transfer heat from the iron to the components being joined. Any obstruction, such as solidified solder, can interfere with this process. As a result, the iron may not generate enough heat to melt the solder properly, and the joint may not be strong or reliable.

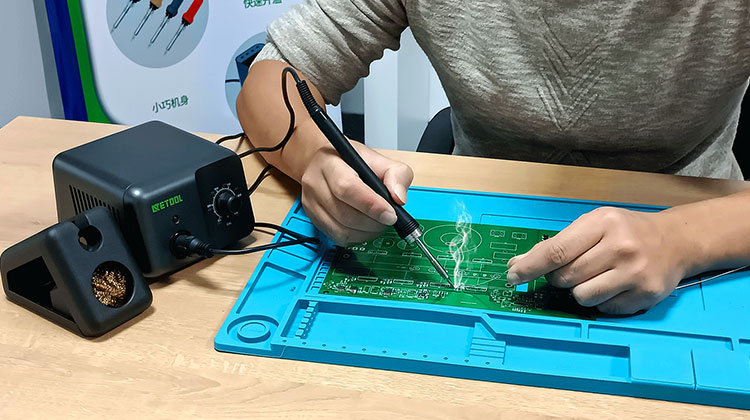

Third, leaving solder on the iron's tip can increase the risk of accidents, such as burns or fires. Soldering irons get very hot, and if the tip is covered in solidified solder, it can be more difficult to control. This can increase the risk of burns or other injuries, particularly if the iron is handled carelessly or accidentally comes into contact with flammable materials. In addition, the solidified solder on the tip of the iron can become heated and ignite, causing a fire hazard.

Fourth, leaving solder on the tip of the iron can damage the iron itself. Solder is a metal alloy composed of a mixture of metals, which can corrode or oxidize over time. If the iron tip is covered in solidified solder, the solder can corrode or oxidize, and this corrosion can damage the iron's tip. Over time, the tip can become pitted, eroded, or otherwise damaged, reducing its effectiveness and shortening its lifespan.

In conclusion, it is generally not recommended to leave solder on the tip of a soldering iron, as this can cause various problems. Solder can solidify and form a crust on the tip of the iron, making it difficult to use and reducing its ability to transfer heat to the components being joined. In addition, leaving solder on the tip of the iron can increase the risk of accidents, such as burns or fires, and can damage the iron itself. To avoid these problems, it's important to clean the tip of the iron regularly, to remove any solidified solder, and to maintain the iron properly.

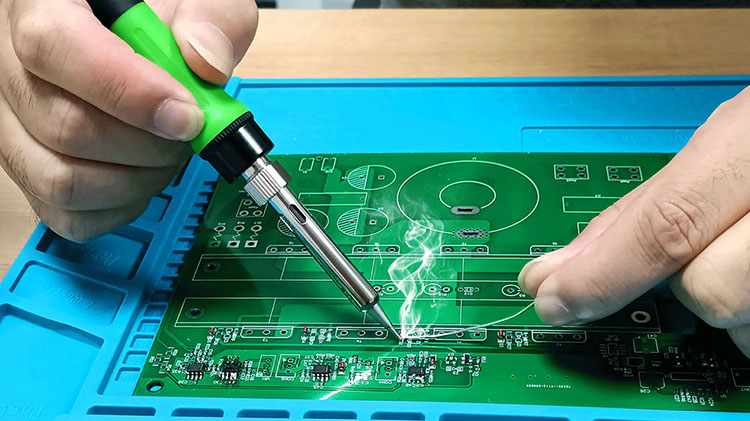

To avoid leaving solder on the tip of the iron, there are several steps that you can take. First, it's important to clean the tip of the iron regularly to remove any solidified solder that may be present. This can be done using a damp sponge or brass wool and can be done before and after each use of the iron. By cleaning the tip regularly, you can help prevent the solidified solder buildup and ensure that the iron is ready to use at any time.

Second, using the correct soldering technique is important to avoid leaving excess solder on the iron's tip. When soldering, it's important to apply the correct amount of heat and solder to the joint and remove the iron from the joint as soon as it has melted and flowed properly. By avoiding the application of excess heat and solder, you can help prevent the formation of a solidified crust on the iron's tip.

Third, it's important to use the correct type and size of soldering iron for the job. Different types and sizes of soldering irons are designed for use with different types and sizes of components, and it's important to choose the correct iron for the job. Using the correct iron can help ensure that the correct amount of heat and solder is applied to the joint and can reduce the risk of leaving excess solder on the iron's tip.

Fourth, it's important to maintain the soldering iron properly to ensure it is in good working order. This includes cleaning the tip regularly, as mentioned above, and replacing the tip when it becomes worn or damaged. In addition, it's important to clean the iron itself regularly, to remove any dirt or debris that may be present, and to store the iron in a safe and appropriate location when it is not in use. By maintaining the iron properly, you can help to prevent problems and extend its lifespan.

In conclusion, leaving solder on the tip of a soldering iron can cause various problems, and it is generally not recommended. To avoid leaving solder on the tip of the iron, it's important to clean the tip regularly, to use the correct soldering technique, to use the correct type and size of iron, and to maintain the iron properly. By following these steps, you can help ensure that your soldering work is successful and reliable and can avoid the problems caused by leaving solder on the tip of the iron.

Contact: Mr. Li

Phone: (0086) 138 24254 321

E-mail: atetool@atetool.com.cn

Add: 5F, 1-2# Building, Tongfuyu Industrial Zone, Aiqun Rd, Shiyan Subdistrict, Bao'an, Shenzhen, 518108, China