People make many common mistakes when soldering, which can lead to a variety of problems, including weak or unreliable joints, damaged components, and safety hazards. Some of the most common soldering mistakes include:

1. Using the wrong type of solder: Different types of solder have different melting points and are designed for use with specific types of metals and applications. Using the wrong type of solder can result in a weak or unreliable joint or can cause damage to the components being joined.

2. Not using enough heat: Solder melts at a relatively low temperature, and it's important to apply enough heat to the joint to ensure that the solder melts and flows properly. If too little heat is applied, the solder may not properly melt or flow into the joint, resulting in a weak or unreliable connection.

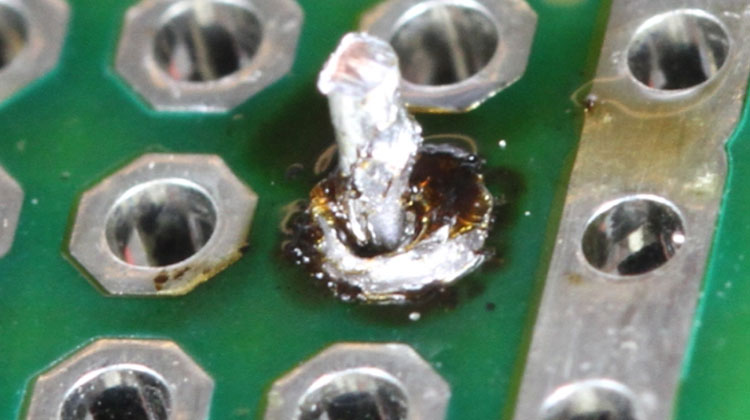

3. Applying too much heat: On the other hand, applying too much heat to a soldering joint can cause problems. Excessive heat can damage the joined components or cause the solder to flow too quickly, creating a messy or unreliable joint.

4. Not cleaning the components properly: Before soldering, it's important to clean the surfaces of the components being joined to remove any dirt, grease, or oxidation that may be present. If the components are not cleaned properly, the solder may not adhere properly to the surfaces, resulting in a weak or unreliable joint.

5. Not using flux: Flux is a chemical compound applied to the surfaces of the components being joined to help the solder flow and adhere properly. If the flux is not used, the solder may not flow properly or adhere to the components' surfaces, resulting in a weak or unreliable joint.

6. Not using the correct soldering iron: Soldering irons come in many different sizes and types, and choosing the correct soldering iron for the job is important. If the soldering iron is too small or too weak, it may not be able to generate enough heat to melt the solder properly. On the other hand, if the soldering iron is too large or too powerful, it can damage the joined components or cause the solder to flow too quickly, creating a messy or unreliable joint.

7. Not maintaining the soldering iron properly: In addition to choosing the correct soldering iron, it's also important to maintain it properly. This includes cleaning the tip regularly to remove any dirt or oxidation that may be present and replacing the tip when it becomes worn or damaged. If the soldering iron is not maintained properly, it may not be able to generate enough heat to melt the solder properly or may cause damage to the components being joined.

8. Not using the correct soldering technique: Soldering is a skill that requires practice and attention to detail. If the correct soldering technique is not used, the solder may not flow properly or adhere to the surfaces of the components, resulting in a weak or unreliable joint.

9. Not using the correct soldering tools: In addition to the soldering iron, there are many other tools and accessories that are useful for solderings, such as soldering stations, desoldering tools, and magnifying glasses. Using the correct tools can make soldering easier and more accurate and help avoid common mistakes.

10. Not wearing the correct safety equipment: Soldering involves the use of heat, chemicals, and potentially hazardous materials, and it's important to wear the correct safety equipment to protect yourself and others. This includes safety glasses to protect your eyes, gloves to protect your hands, and a mask to protect your respiratory system.

11. Not working in a well-ventilated area: Soldering can produce harmful fumes and particles, and it's important to work in a well-ventilated area to avoid inhaling these substances. This includes using a fan or other ventilation system to remove the fumes from the workspace and avoiding soldering in enclosed or poorly-ventilated areas.

12. Not following the instructions: Finally, one of the most common soldering mistakes is not following the instructions. Whether using a soldering kit, following a tutorial, or working from a schematic, it's important to read and understand the instructions carefully and follow them step-by-step. This can help avoid common mistakes and ensure that your soldering work is successful and reliable.

In conclusion, there are many common soldering mistakes that people make, and these mistakes can lead to a variety of problems. Some of the most common soldering mistakes include using the wrong type of solder, not applying enough or too much heat, not cleaning the components properly, not using flux, not using the correct soldering iron, not maintaining the soldering iron properly, not using the correct soldering technique, not using the correct soldering tools, not wearing the correct safety equipment, not working in a well-ventilated area, and not following the instructions. By avoiding these mistakes, you can help to ensure that your soldering work is successful and reliable.

Contact: Mr. Li

Phone: (0086) 138 24254 321

E-mail: atetool@atetool.com.cn

Add: 5F, 1-2# Building, Tongfuyu Industrial Zone, Aiqun Rd, Shiyan Subdistrict, Bao'an, Shenzhen, 518108, China