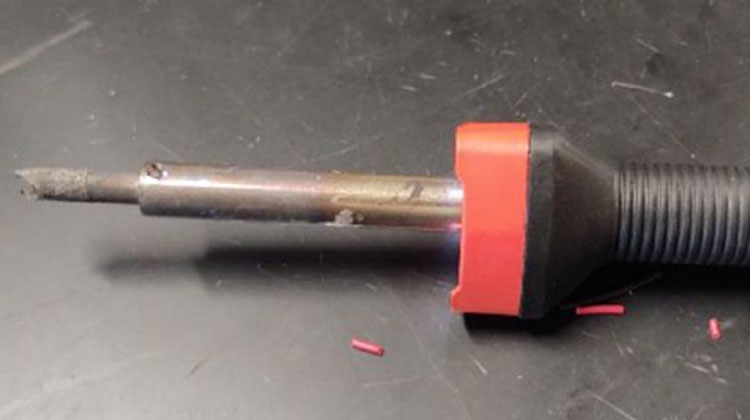

Sanding a soldering iron tip can be a useful way to improve its performance and extend its lifespan. Still, it's important to do it carefully and correctly to avoid damaging the tip or the iron itself. Sanding the tip of a soldering iron can remove any oxide or contamination that may be present and can improve its ability to transfer heat to the components being joined. However, if the sanding is not done properly, it can damage the iron's tip and reduce its effectiveness and reliability.

There are several steps you can follow when sanding the tip of a soldering iron to ensure that the process is done safely. It may be necessary to replace the tip with a new one for artefactual evidence or other indicators that suggest that the tip has been damaged or worn out. This will help to ensure that the soldering iron is in good working order and can transfer heat effectively to the components being joined.

Additionally, it's important to remember that sanding the tip of a soldering iron is only one part of maintaining it and ensuring it is in good working order. In addition to sanding the tip, it's also important to clean the iron regularly, remove any dirt or debris that may be present, and store the iron in a safe and appropriate location when it is not in use. By following these steps, you can ensure that your soldering iron is in good working order and can transfer heat effectively to the joined components.

Another important consideration when sanding the tip of a soldering iron is the type of sandpaper or abrasive material used. Different types of sandpaper or abrasive materials have different grit sizes, and it's important to choose the correct grit size for the task. Generally speaking, a fine-grit sandpaper or abrasive material is best for sanding the tip of a soldering iron, as this will remove any oxide or contamination that may be present without damaging the tip. Coarse grit sandpapers or abrasive materials should be avoided, as they can damage the iron's tip and reduce its effectiveness.

Finally, it's important to remember that sanding the tip of a soldering iron is not a substitute for regular maintenance and care. Over time, the tip of a soldering iron can wear out or become damaged, and it may be necessary to replace it with a new one. If the tip of the iron is damaged or worn out, sanding it will not restore its effectiveness, and it may be necessary to replace the tip to ensure that the iron is in good working order. By following the steps outlined above and by inspecting the tip of the iron regularly for signs of wear or damage, you can help ensure that your soldering iron is in good working order and can transfer heat effectively to the components being joined.

Contact: Mr. Li

Phone: (0086) 138 24254 321

E-mail: atetool@atetool.com.cn

Add: 5F, 1-2# Building, Tongfuyu Industrial Zone, Aiqun Rd, Shiyan Subdistrict, Bao'an, Shenzhen, 518108, China