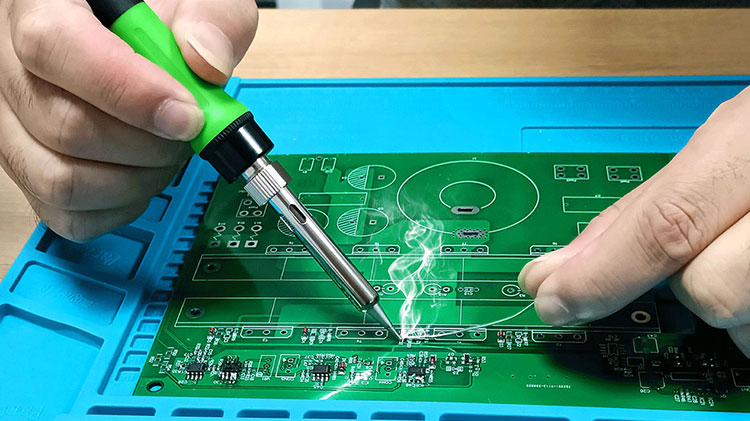

While soldering, there are a few things you should not do to avoid damaging the soldered joint and ensure the success of your soldering project. Here are a few things that you should not do while soldering:

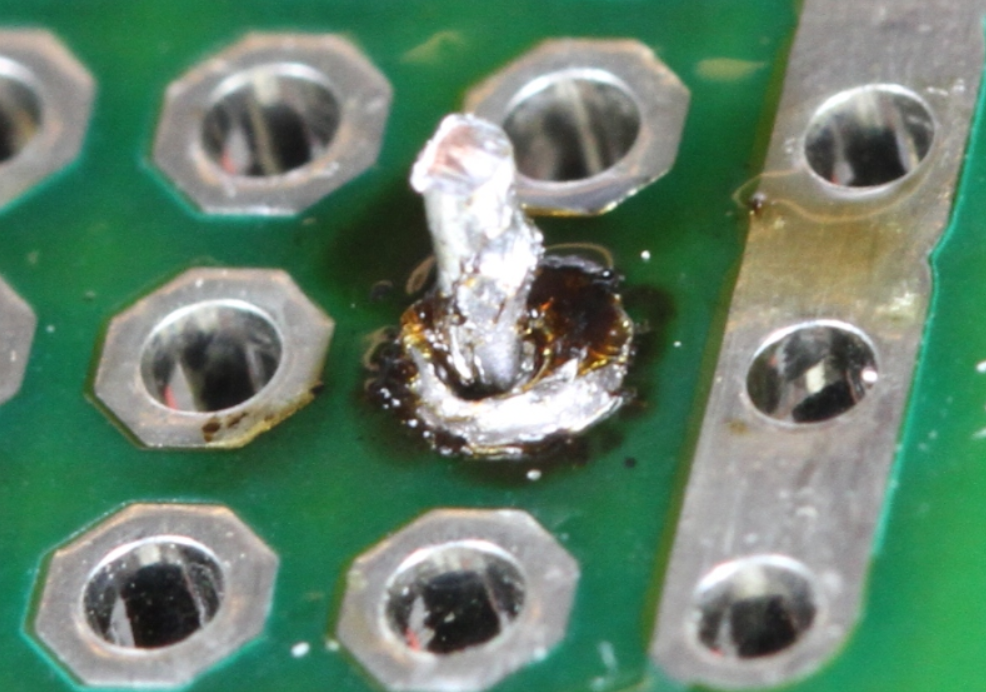

1. Do not overheat the soldered joint: While soldering, it is important to avoid overheating the soldered joint, as this can cause damage, such as warping, cracking, or melting. Overheating the soldered joint can also weaken and reduce its strength and durability. To avoid overheating the soldered joint, it is important to use the right temperature and technique for the specific application.

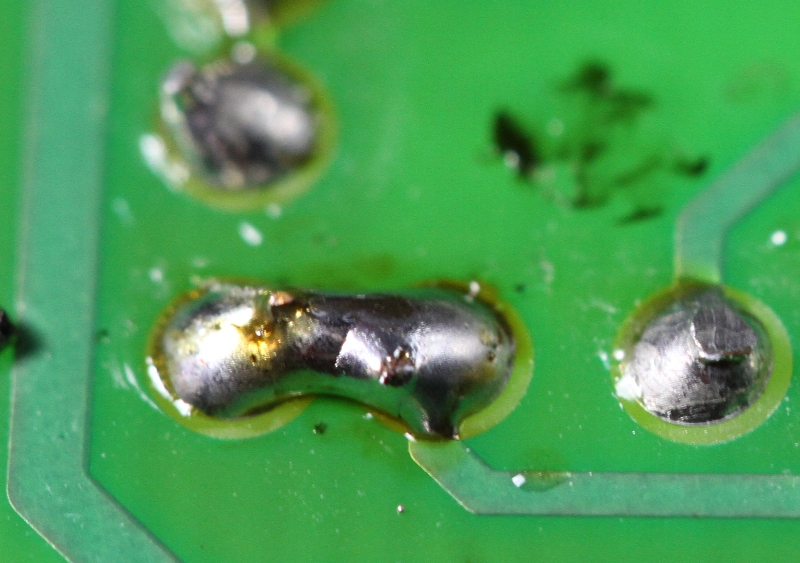

2. Do not apply too much solder: While soldering, it is important to avoid applying too much solder, as this can cause excess solder to build up on the soldered joint, and it can create a weak and brittle joint. Applying too much solder can also create a messy and unsightly joint, making it difficult to remove the excess solder. To avoid applying too much solder, it is important to use the right amount and technique for the specific application.

3. Do not move or reposition the metal parts while soldering: It is important to avoid moving or repositioning the metal parts, as this can cause the soldered joint to break or fail. Moving or repositioning the metal parts while soldering can also cause the solder to spread or flow in the wrong direction, creating a weak and unreliable joint. To avoid moving or repositioning the metal parts while soldering, secure the parts and use clamps or other restraints if necessary.

4. Do not use a damaged or faulty soldering iron: While soldering, it is important to avoid using a damaged or faulty soldering iron, as this can cause accidents, injuries, or damage to the soldered joint. A damaged or faulty soldering iron can have various problems, such as a loose or damaged heating element, a broken or damaged handle, or malfunctioning temperature control. To avoid using a damaged or faulty soldering iron, it is important to check the iron before use and replace or repair it if necessary.

During soldering, there are a few things that you should not do to avoid damaging the soldered joint and to ensure the success of your soldering project. These include: not overheating the soldered joint, not applying too much solder, not moving or repositioning the metal parts while soldering, and not using a damaged or faulty soldering iron. By following these guidelines, you can avoid damaging the soldered joint and ensure that your soldering project is successful.

In addition to the things you should not do while soldering, there are also a few things you should do to ensure the success of your soldering project. Here are a few things that you should do while soldering:

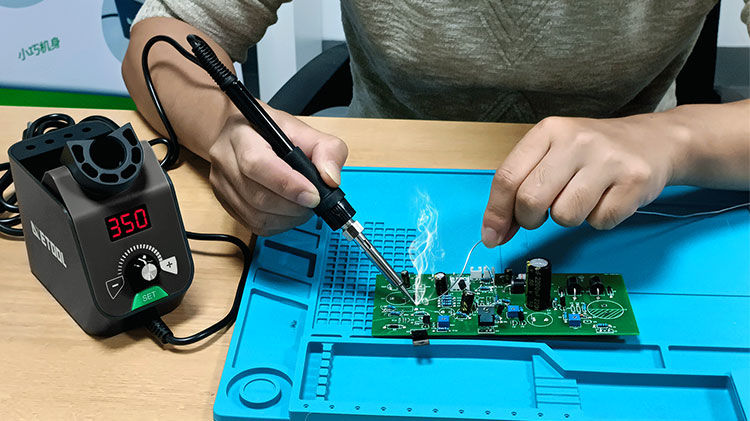

1. Use the right temperature and technique: While soldering, it is important to use the right temperature and technique for the specific application. Different types of solders have different melting points, and different metals have different heat tolerances. Using the wrong temperature or technique can cause damage, such as warping, cracking, or melting, weakening the soldered joint.

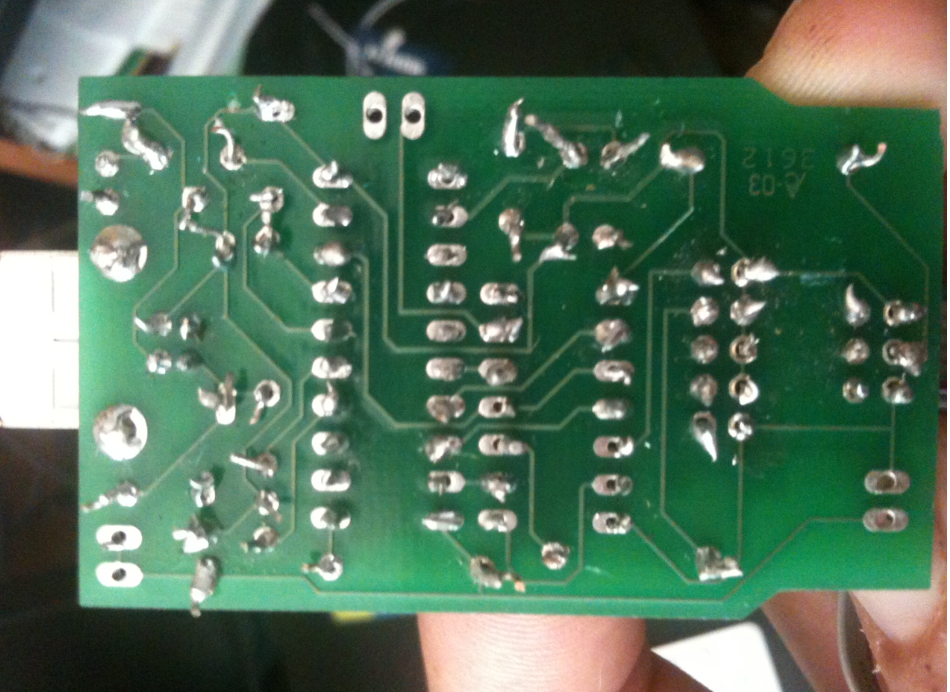

2. Apply the solder in the right amount and location: While soldering, it is important to apply the solder in the right amount and location to create a strong and durable joint. Applying the solder in the wrong amount or location can result in a weak and brittle joint, and it can cause the joint to break or fail under stress or pressure. To apply the solder in the right amount and location, it is important to use the right tools and techniques and to follow the instructions provided by the manufacturer.

3. Use flux to clean and protect the metal surfaces: While soldering, it is important to use flux to clean and protect the metal surfaces. Flux is a chemical agent applied to metal surfaces before soldering, and it helps remove oxide, dirt, and other contaminants from the surfaces. Flux also helps to protect the metal surfaces from oxidation and corrosion, and it promotes the formation of a strong and durable soldered joint. To use flux, it is important to apply the flux according to the instructions provided by the manufacturer.

4. Wear protective equipment and clothing: While soldering, it is important to wear protective equipment and clothing to avoid accidents, injuries, or exposure to hazardous materials. Protective equipment and clothing can include gloves, eyewear, masks, and aprons, and they can help to protect you from the heat, fumes, and sparks of the soldering process. To wear protective equipment and clothing, it is important to follow the instructions provided by the manufacturer and to use the equipment and clothing according to the guidelines provided by your employer or safety officer.

In conclusion, while soldering, there are a few things that you should do to ensure the success of your soldering project. These include: using the right temperature and technique, applying the solder in the right amount and location, using flux to clean and protect the metal surfaces, and wearing protective equipment and clothing. By following these guidelines, you can avoid damaging the soldered joint and ensure that your soldering project is successful.

Contact: Mr. Li

Phone: (0086) 138 24254 321

E-mail: atetool@atetool.com.cn

Add: 5F, 1-2# Building, Tongfuyu Industrial Zone, Aiqun Rd, Shiyan Subdistrict, Bao'an, Shenzhen, 518108, China