Before soldering, there are a few things that you should not do in order to avoid damaging the soldered joint and to ensure the success of your soldering project. Here are a few things that you should not do before soldering:

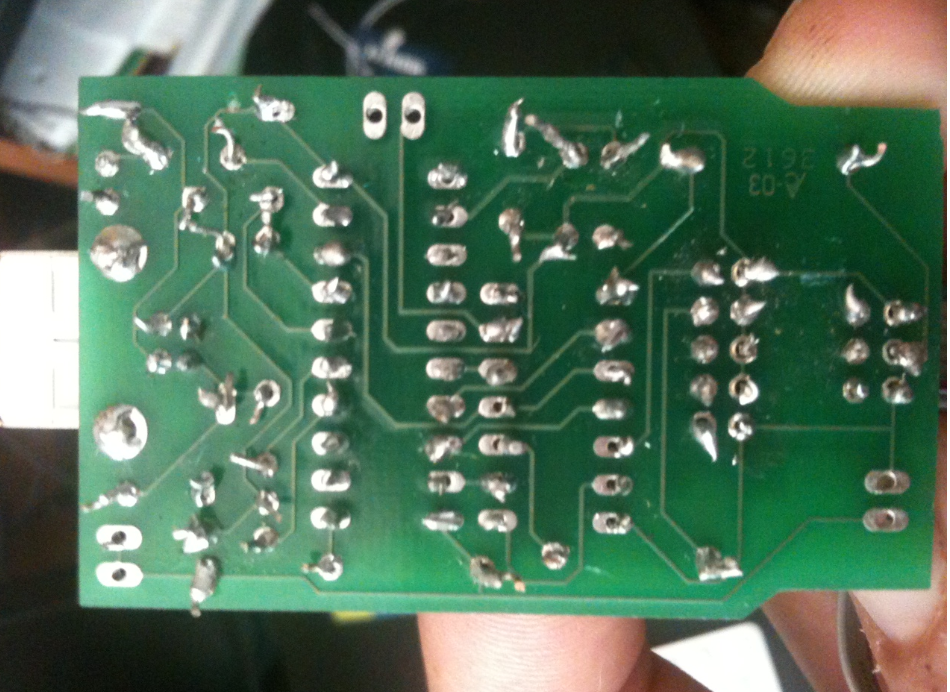

1. Do not use dirty or contaminated metal parts: Before soldering, it is important to avoid using dirty or contaminated metal parts, as this can cause defects or flaws in the soldered joint, and it can weaken the joint. Contaminants, such as oxide, dirt, grease, or oil, can prevent the solder from adhering to the metal surfaces, and they can create a weak and brittle joint. To avoid using dirty or contaminated metal parts, it is important to clean the parts before soldering and to remove any contaminants using a solvent, such as alcohol or acetone.

2. Do not use damaged or faulty metal parts: Before soldering, it is important to avoid using damaged or faulty metal parts, as this can cause accidents, injuries, or damage to the soldered joint. Damaged or faulty metal parts can have various problems, such as cracks, dents, or deformations, and they can compromise the strength and durability of the soldered joint. To avoid using damaged or faulty metal parts, it is important to inspect the parts before soldering and to replace or repair the parts if necessary.

3. Do not use old or expired soldering supplies: Before soldering, it is important to avoid using old or expired soldering supplies, as this can cause defects or flaws in the soldered joint, and it can weaken the joint. Soldering supplies, such as solder, flux, and soldering paste, have a limited shelf life and can become ineffective or unreliable over time. To avoid using old or expired soldering supplies, it is important to check the expiration dates of the supplies before use and to replace or discard the supplies if necessary.

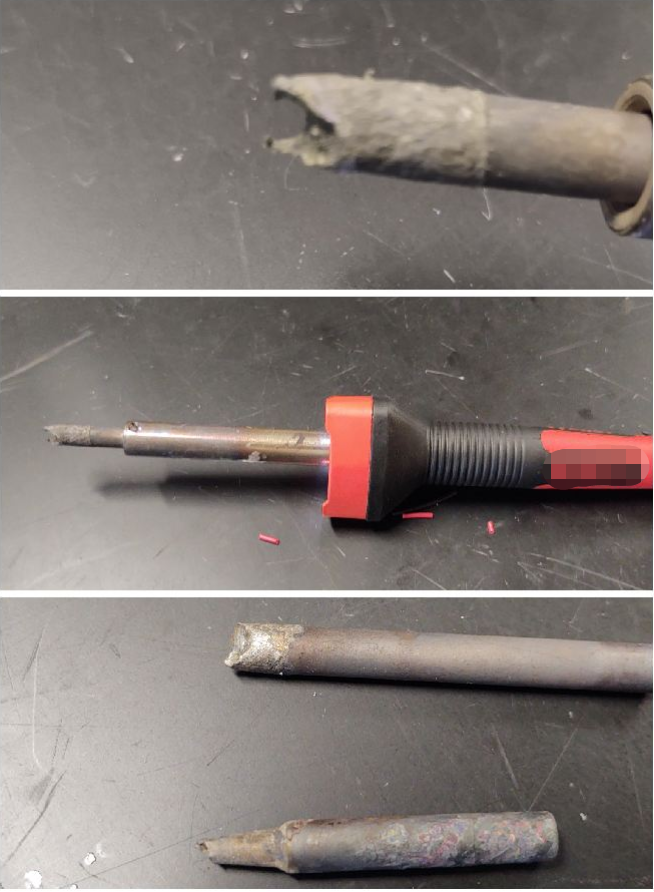

4. Do not use a damaged or faulty soldering iron: Before soldering, it is important to avoid using a damaged or faulty soldering iron, as this can cause accidents, injuries, or damage to the soldered joint. A damaged or faulty soldering iron can have a variety of problems, such as a loose or damaged heating element, a broken or damaged handle, or malfunctioning temperature control. To avoid using a damaged or faulty soldering iron, it is important to check the iron before use and replace or repair it if necessary.

In short, before soldering, there are a few things that you should not do to avoid damaging the soldered joint and to ensure the success of your soldering project. These include: not using dirty or contaminated metal parts, not using damaged or faulty metal parts, not using old or expired soldering supplies, and not using a damaged or faulty soldering iron. By following these guidelines, you can avoid damaging the soldered joint and ensure that your soldering project is successful.

In addition to the things you should not do before soldering, there are also a few things you should do to ensure the success of your soldering project. Here are a few things that you should do before soldering:

1. Clean the metal parts: Before soldering, it is important to clean the metal parts to remove any contaminants, such as oxide, dirt, grease, or oil. Cleaning the metal parts will help ensure that the solder adheres to the metal surfaces, creating a strong and durable soldered joint. To clean the metal parts, you can use a solvent, such as alcohol or acetone, and a soft cloth or brush.

2. Inspect the metal parts for defects or flaws: Before soldering, it is important to inspect the metal parts for defects or flaws, such as cracks, dents, or deformations. These defects can weaken the soldered joint and reduce its strength and durability. If you notice any defects or flaws in the metal parts, you should repair or replace the parts before soldering in order to ensure the success of your soldering project.

3. Check the expiration dates of the soldering supplies: Before soldering, it is important to check the expiration dates of the soldering supplies, such as solder, flux, and soldering paste. Soldering supplies have a limited shelf life and can become ineffective or unreliable over time. To avoid using old or expired soldering supplies, it is important to check the expiration dates of the supplies before use and to replace or discard the supplies if necessary.

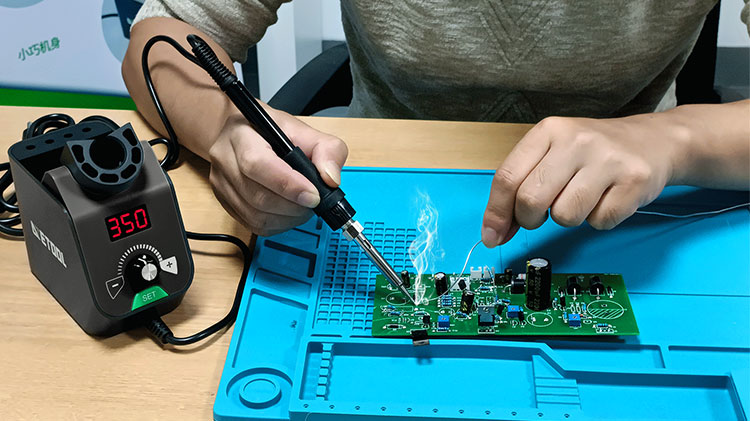

4. Test the soldering iron: Before soldering, it is important to ensure that it is functioning properly. A faulty or damaged soldering iron can cause accidents, injuries, or damage to the soldered joint and compromise the success of your soldering project. To test the soldering iron, you can use a test piece of metal or a spare component and adjust the temperature and technique as necessary.

In conclusion, before soldering, there are a few things that you should do to ensure the success of your soldering project. These include: cleaning the metal parts, inspecting the parts for defects or flaws, checking the expiration dates of the soldering supplies, and testing the soldering iron. By following these guidelines, you can avoid damaging the soldered joint and ensure that your soldering project is successful. Additionally, taking the time to prepare for your soldering project will save you time and effort in the long run and help you avoid common mistakes and pitfalls.

Contact: Mr. Li

Phone: (0086) 138 24254 321

E-mail: atetool@atetool.com.cn

Add: 5F, 1-2# Building, Tongfuyu Industrial Zone, Aiqun Rd, Shiyan Subdistrict, Bao'an, Shenzhen, 518108, China