The temperature at which you solder depends on the solder type and the application. Solder is available in different alloys, each with its melting point, and the temperature required for soldering will vary depending on the type of alloy being used.

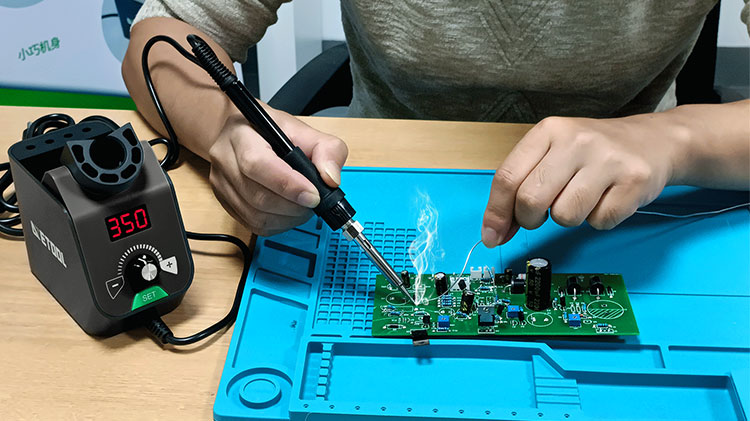

A soldering temperature of 350 and 400 degrees Celsius is recommended for most applications. This is the temperature range at which most solders will melt and flow easily without vaporizing or damaging the soldered components.

For example, lead-free solders, commonly used in electronics and other applications, typically have a melting point between 180 to 220 degrees Celsius. To achieve a good soldered joint with lead-free solder, the soldering iron should be set to a temperature of around 350 to 400 degrees Celsius.

On the other hand, some alloys, such as silver-based solders, have higher melting points. Silver-based solders are commonly used in jewelry making and other applications where a strong, durable soldered joint is required. These solders typically have a melting point in the range of 600 to 800 degrees Celsius. To achieve a good soldered joint with silver-based solder, the soldering iron should be set to a temperature of around 700 to 800 degrees Celsius.

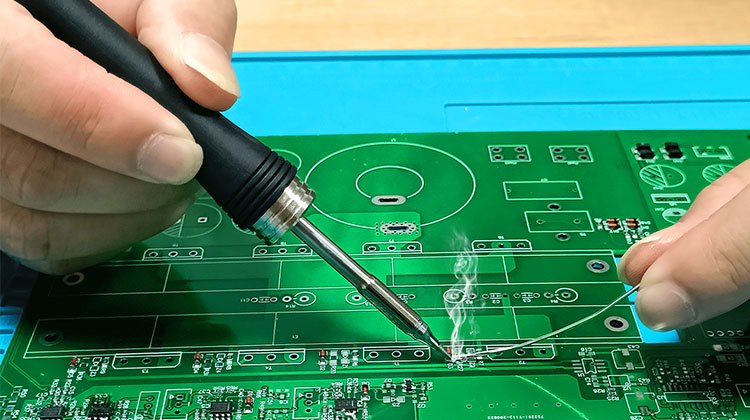

It's important to note that the temperature of the soldering iron is not the only factor affecting the soldered joint's temperature. The temperature of the soldered components, the PCB, and the surrounding environment can also affect the temperature of the soldered joint. For example, if the components or PCB are cold, they will absorb heat from the soldering iron and reduce the temperature of the soldered joint.

In conclusion, the temperature at which you solder depends on the type of solder being used. A soldering temperature of between 350 and 400 degrees Celsius is recommended for most solders. However, some alloys, such as silver-based solders, may require higher temperatures. It's important to carefully choose the right temperature for your soldering application to ensure that the solder flows properly and creates a strong, reliable soldered joint.

In addition to choosing the right temperature for soldering, it's also important to use the right type of iron. The type of soldering iron that you use will affect the temperature of the soldering iron tip, which in turn affects the temperature of the soldered joint.

Several soldering irons are available, each with its own advantages and disadvantages. For example, some soldering irons use a resistive heating element, which is simple and inexpensive but can be slow to heat up and difficult to control the temperature accurately. Other soldering irons use a ceramic heating element, which heats up quickly and allows for more precise temperature control but is more expensive.

Generally, it's best to use a soldering iron with a ceramic heating element because it allows for more precise temperature control. This is especially important for soldering applications requiring specific temperatures, such as silver-based solders requiring higher temperatures.

Another important factor to consider when choosing a soldering iron is the power rating. The power rating of a soldering iron determines how quickly it can heat up and how much heat it can produce. A soldering iron with a power rating of between 20 and 40 watts is sufficient for most soldering applications. However, a soldering iron with a higher power rating may be necessary for applications requiring high temperatures, such as silver-based solders.

It's also important to note that the temperature of the soldering iron can be adjusted to suit the specific application's needs. Many soldering irons are equipped with temperature control features, which allow the user to set the temperature accurately and adjust it as needed.

For example, a temperature-controlled soldering iron can be useful when the components or PCB being soldered have different thermal properties, such as different sizes or shapes. In these cases, the temperature of the soldering iron can be adjusted to ensure that the soldered joint reaches the correct temperature for the specific components and PCB being soldered.

In addition, a temperature-controlled soldering iron can be useful for soldering delicate components or sensitive materials, such as printed circuit boards with thin traces or thin-film resistors. In these cases, the temperature of the soldering iron can be adjusted to a lower setting to avoid damaging the components or traces.

In conclusion, choosing the right temperature for soldering is important for achieving a strong, reliable soldered joint. In choosing the right temperature, it's also important to use the right type of soldering iron, with a ceramic heating element and the appropriate power rating for your soldering application. By carefully selecting the right temperature and soldering iron, you can ensure that your soldered joints are high quality and meet your requirements.

Contact: Mr. Li

Phone: (0086) 138 24254 321

E-mail: atetool@atetool.com.cn

Add: 5F, 1-2# Building, Tongfuyu Industrial Zone, Aiqun Rd, Shiyan Subdistrict, Bao'an, Shenzhen, 518108, China