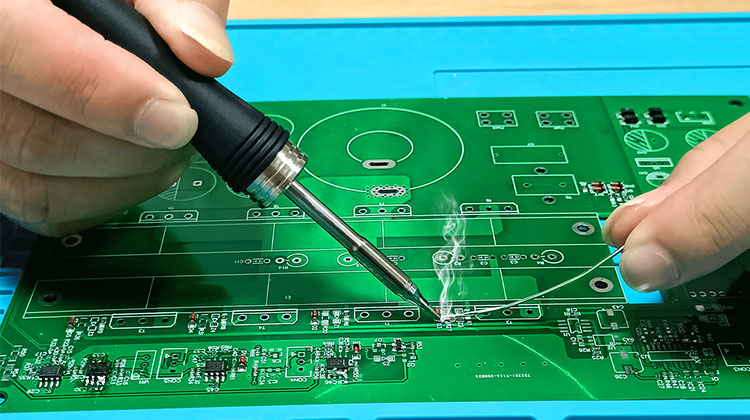

A soldering iron is a tool used to heat up and melt the solder, a type of metal or alloy with a low melting point. The solder is applied to the metal parts that need to be joined together, and the soldering iron is used to heat it up and melt it so that it can flow into the gaps and pores of the metal surfaces and form a strong and durable joint.

The main difference between a solder and a soldering iron is their composition and function. The solder is made of a metal or an alloy, such as lead, tin, copper, or silver, and it has a low melting point, typically between 180 and 400 degrees Celsius, depending on the type of solder and the application. Soldering iron is made of a metal or a composite material, such as iron, steel, copper, or ceramic. It has a high melting point, typically between 600 and 900 degrees Celsius, depending on the type of soldering iron and the power source.

The solder is used to join metal parts by melting it and flowing it into the gaps and pores of the metal surfaces, forming a strong and durable joint. The soldering iron is used to heat up and melt the solder by applying heat to it and allowing it to reach its melting point and flow into the metal parts. The soldering iron is also used to clean, activate, and protect the metal parts by applying flux, removing oxide, dirt, grease, or oil, and preparing them for soldering.

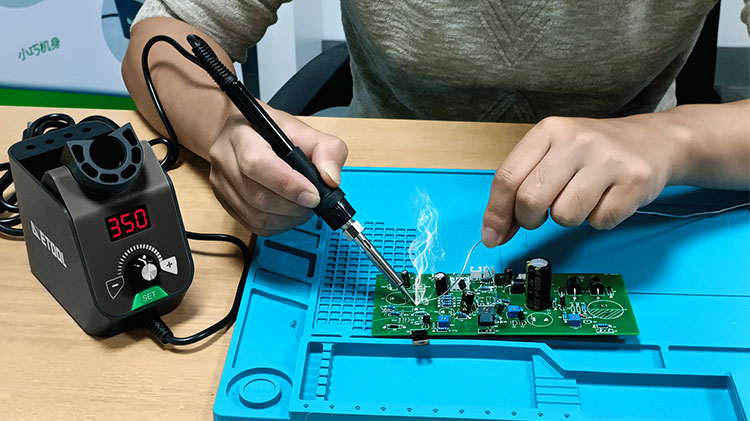

The solder is usually supplied in the form of a wire, a bar, a paste, or a powder, and it is selected according to the type of metal parts, the type of joint, and the application. The soldering iron is usually supplied in the form of a pen, a gun, a torch, or a station, and it is selected according to the type of power source, the type of tip, and the type of handle. The solder and the soldering iron are both essential tools for soldering, and they are used together to create strong and durable soldered joints.

Briefly speaking, the difference between a solder and a soldering iron is their composition and function. The solder is a metal or an alloy used to join metal parts together, and the soldering iron is a tool used to heat up and melt the solder. The solder and the soldering iron are both important tools for soldering, and they are used together to create strong and durable soldered joints.

The selection of the right type of solder and the right type of soldering iron is crucial for the success and quality of the soldering process. The solder must be compatible with the metal parts, and the joint and must have the right melting point, strength, and conductivity for the application. The soldering iron must be compatible with the power source and the tip, and it must have the right temperature, the right power, and the right control for the application.

The use of the solder and the soldering iron must also be done properly and safely to avoid accidents, injuries, or damages. The solder must be handled carefully to avoid spilling, splashing, or inhaling and must be stored properly to avoid contamination, corrosion, or decomposition. The soldering iron must be handled carefully to avoid burns, shocks, or fires, and it must be maintained properly to avoid wear, tear, or failure.

The solder and the soldering iron must also be used in the right sequence and the right sequence to ensure that the soldering process is efficient and effective. The solder must be applied after the flux, and it must be melted and flowed into the metal parts before it cools down and solidifies. The soldering iron must be applied after the metal parts and the flux, and it must be heated up and maintained at the right temperature during the soldering process.

The solder and the soldering iron must also be used in the right amount and the right amount to avoid excess, waste, or defects. The solder must be applied in the right amount to avoid gaps, voids, or excess, and it must be removed in the right amount to avoid waste, contamination, or damage. The soldering iron must be applied correctly to avoid overheating, underheating, or burnout, and it must be removed in the right amount to avoid waste, contamination, or damage.

In conclusion, the use of solder and the soldering iron is an essential part of the soldering process. It must be done properly, safely, and efficiently to create strong, durable, soldered joints. By selecting the right solder and soldering iron, using them properly and safely, and applying them in the right sequence and the right amount, the solderer can become a skilled and confident solderer. They can create strong and durable soldered joints.

Contact: Mr. Li

Phone: (0086) 138 24254 321

E-mail: atetool@atetool.com.cn

Add: 5F, 1-2# Building, Tongfuyu Industrial Zone, Aiqun Rd, Shiyan Subdistrict, Bao'an, Shenzhen, 518108, China