Soldering is a technique that involves the use of heat and filler metal to create a strong and durable bond between two metal surfaces. Although soldering is a versatile and effective technique, it does not work on all metals, and some metals are unsuitable for soldering.

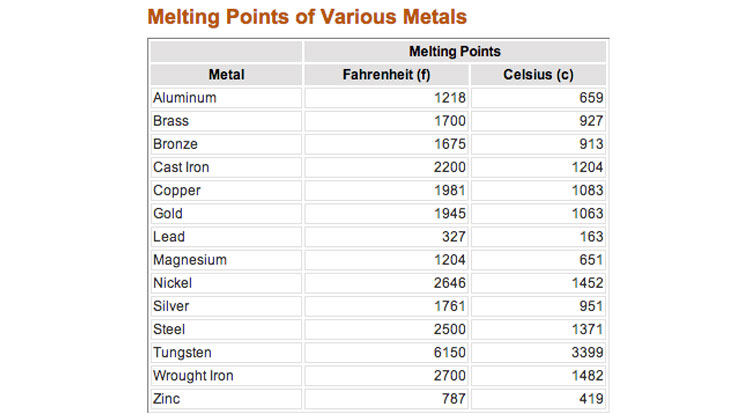

One of the main factors determining whether soldering will work on a particular metal is the melting point of the metal. In soldering, the metal surfaces are heated to a temperature below the melting point of the filler metal, and the filler metal is applied in a liquid form. The heat from the soldering iron melts the filler metal, and it flows into the joint, creating a strong and durable bond.

If the melting point of the metal being joined is too high, it will not be possible to heat the metal surfaces to a temperature below the melting point of the filler metal. In this case, the filler metal will not melt, and it will not be possible to create a strong and durable bond. For example, steel and cast iron have high melting points and are not suitable for soldering.

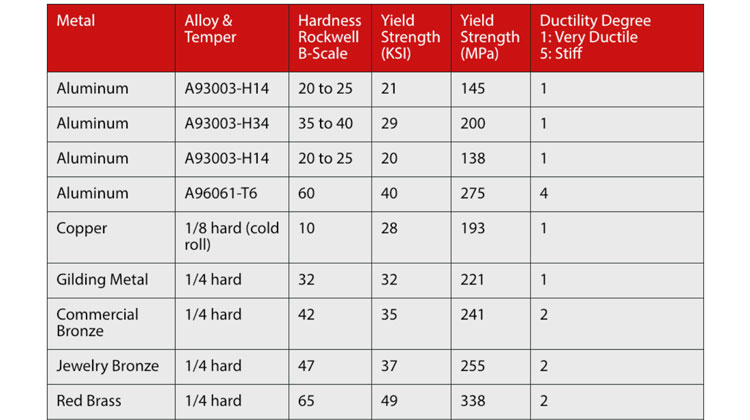

Another factor that determines whether soldering will work on a particular metal is the hardness of the metal. In soldering, the metal surfaces must be soft enough to be deformed by the heat and the pressure of the filler metal. If the metal is too hard, it will not be possible to create a gap between the two surfaces, and the filler metal will not be able to flow into the joint. For example, hard metals such as tungsten and titanium are not suitable for soldering.

In addition to the melting point and the hardness of the metal, several other factors can affect the success of soldering on a particular metal. For example, some metals, such as copper and brass, are more prone to oxidation and other contaminants, which can interfere with the soldering process. In these cases, it may be necessary to use flux, a chemical compound that removes oxidation and other contaminants from the metal surfaces, to ensure a strong and durable bond.

In brief, soldering is a versatile and effective technique, but it does not work on all metals. The melting point and the hardness of the metal, as well as other factors, can affect the success of soldering on a particular metal. In general, metals with low melting points and low hardness, such as copper and brass, are suitable for soldering, while metals with high melting points and high hardness, such as steel and cast iron, are not suitable for soldering. By considering the specific characteristics of the metal being joined, you can determine whether soldering is suitable for your application.

It is important to note that, even for metals that are suitable for soldering, the success of the soldering process can be affected by other factors, such as the quality of the filler metal and the soldering iron and the skill and experience of the person performing the soldering. To ensure the best possible results, it is recommended that you use high-quality filler metal and a high-quality soldering iron and that you follow proper soldering techniques and procedures.

Soldering is a suitable technique for a wide range of applications, including electronics and electrical work, metalwork and jewelry making, plumbing and HVAC, and many others. By understanding the specific characteristics of the metals being joined and using high-quality materials and proper soldering techniques, you can ensure the success of your soldering project and create strong and durable bonds between metal surfaces.

In addition to the factors mentioned above, there are several other considerations to keep in mind when deciding whether soldering is a suitable technique for your application. One of these considerations is the required strength and durability of the joint. In some cases, a strong and durable joint may be essential, such as in constructing a bridge or a building. In these cases, soldering may not be the best option because it may not provide the required strength and durability level. In these cases, welding or brazing may be more suitable techniques.

Another consideration is the cost and availability of materials and equipment. Soldering requires the use of specific materials and equipment, such as flux, filler metal, and a soldering iron or torch. In some cases, these materials and equipment may be expensive or difficult to obtain, affecting the feasibility of soldering as a technique. In these cases, alternative techniques, such as riveting or mechanical fastening, may be more suitable.

In conclusion, soldering is a versatile and effective technique. Still, it does not work on all metals, and there are several factors to consider when deciding whether soldering is a suitable option for your application. By understanding the specific characteristics of the metals being joined and by considering the strength and durability of the joint, the cost and availability of materials and equipment, and other factors, you can determine whether soldering is a suitable technique for your project, and you can ensure the success of your soldering project.

Contact: Mr. Li

Phone: (0086) 138 24254 321

E-mail: atetool@atetool.com.cn

Add: 5F, 1-2# Building, Tongfuyu Industrial Zone, Aiqun Rd, Shiyan Subdistrict, Bao'an, Shenzhen, 518108, China